Preventative maintenance is one of the easiest ways to spend a buck now and later avoid unnecessary capital expenditures. There are several things that can cause issues in a wastewater system, specifically within lift station and grease interceptor (GI) components, the negative impact of which can be decreased with routine preventative maintenance schedules.

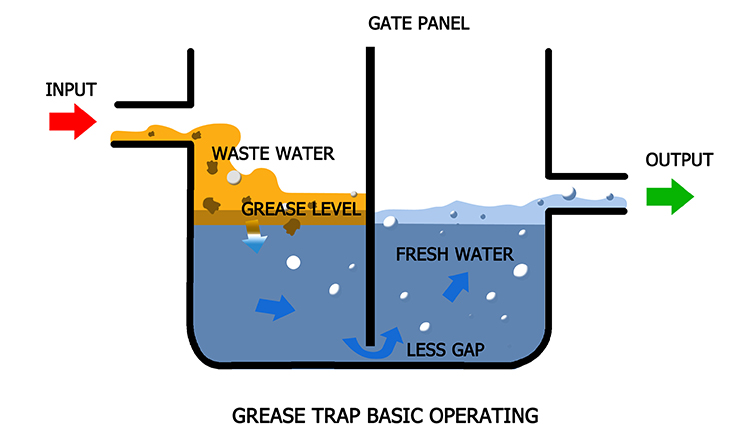

Many facility engineers believe pumping a grease interceptor is adequate enough for preventative maintenance of the system, but the overall health and wellness of the wastewater system requires more than just a pump-out. Neglected grease interceptors can result in multiple issues.

The Issues:

- Buildup of grease in pipes leading to and from GI causing backups and overflows.

- Odors emitting from the GI and/or floor drains.

- Formation of hydrogen sulfide, a toxic and corrosive gas.

- Allowing a spot for rodents and insects to thrive and breed.

- Physical failures of the GI itself (i.e., corrosion).

The Solutions:

- Add Odor Punch™ or Odor Shock™ to the GI system. They provide an easier, obtainable oxygen source for the bacteria in GI’s that are responsible for hydrogen sulfide production.

- Introduce live, vegetative bacteria into the system. These bacteria reduce the amount of fats, oils, and grease buildup on the pipes, and reduce other odors related to grease buildup. The byproducts of biological grease degradation are water and carbon dioxide.

- A combination of both nitrates and bacteria has proven to be most effective for GI maintenance. Odor Punch™ and Odor Shock™, along with biologicals (Bio-Amp™), provide an excellent grease interceptor maintenance program for grease build-up issues and odor control.

These techniques are safe and can provide a natural and effective preventative maintenance program for a GI, saving you both time and money.

Our representatives at Chemsearch FE are extremely knowledgeable about these topics as well as many other facility maintenance areas. If you’d like to discuss further facility solutions with one of our resource management experts, please click here and we will get someone in touch with you soon!

Co-Written by Account Managers, Nick and Carrie